Universitas Gadjah Mada’s (UGM) lecturer has made a batik tulis (handmade batik) printing machine that can produce batik cloth in a shorter period of time.

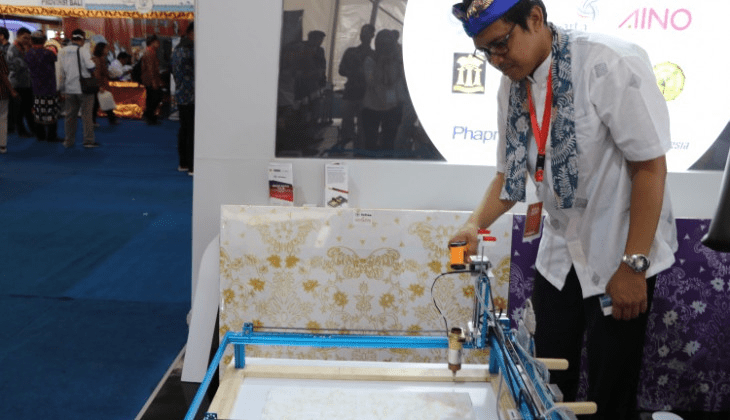

The machine, Butimo, is an innovation made by Mechanical Engineering and Industry lecturer, Andi Sudiarso, Ph.D. Typical batik processing takes 6 hours, while using this machine it takes only 3 hours.

“Using this tool can produce 8 – 10 sheets of batik tulis,” said Andi on Wednesday (29/8) during Ritech Expo 2019 in Bali.

The tool can also save the use of wax in the printing. Manually it requires 88 grams of wax, whereas with this machine it only requires 57 grams. The wax can also be absorbed better in the fabric.

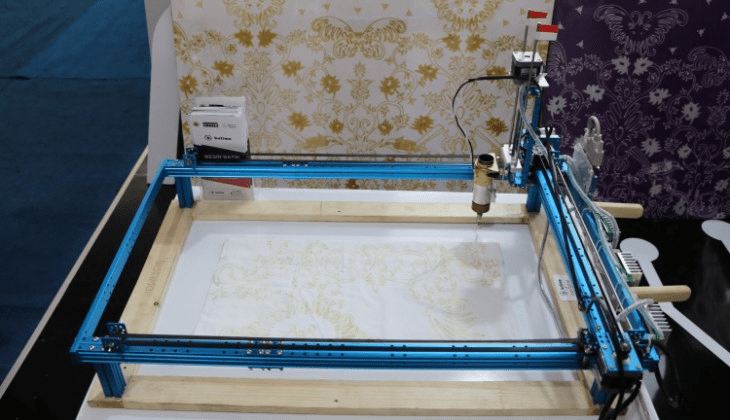

Butimo has 3 axes with a length of 3 – 4 meters and a width of 1.5 meters. It is also equipped with an automatic canting (pen-like tool) change mechanism. The canting comes in different sizes and number of nozzles to be used as required in the design. There are single nozzle, dual nozzle, and multi nozzle cantings that come in various nozzle diameters.

Andi explained that the canting machine is connected a batik tulis machine controlled by CNC. This can do batik processing on a 1.15 m x 2.5 m size fabric or bigger depending on the size of the machine table.

“During the process, a cloth is mounted on a frame to secure the position and quality,” he added.

Andi said this was the first machine he made and a second generation would follow by integrating coloring, and third generation by integrating wax removing process.

Source: https://ugm.ac.id/id/berita/18345-butimo-inovasi-mesin-batik-tulis-karya-peneliti-ugm